SiC Extra High Temperature Process Equipment

SiC Extra High Temperature Process Equipment Series

SiC power device has recently been becoming a key technology to realize a 'low-carbon society'.

We, Toyoko-Kagaku, have worked on a development of SiC thermal process equipment by applying our original extra high temperature technologies since 2000, and thanks to concentrate our long experience, knowhow and the latest technologies, we have succeeded to realize superior quality and performance for SiC thermal processes on our "Ailesic" Series.

"Ailesic" provides tremendous improvement of SiC devise performances and contributes to stability of mass production.

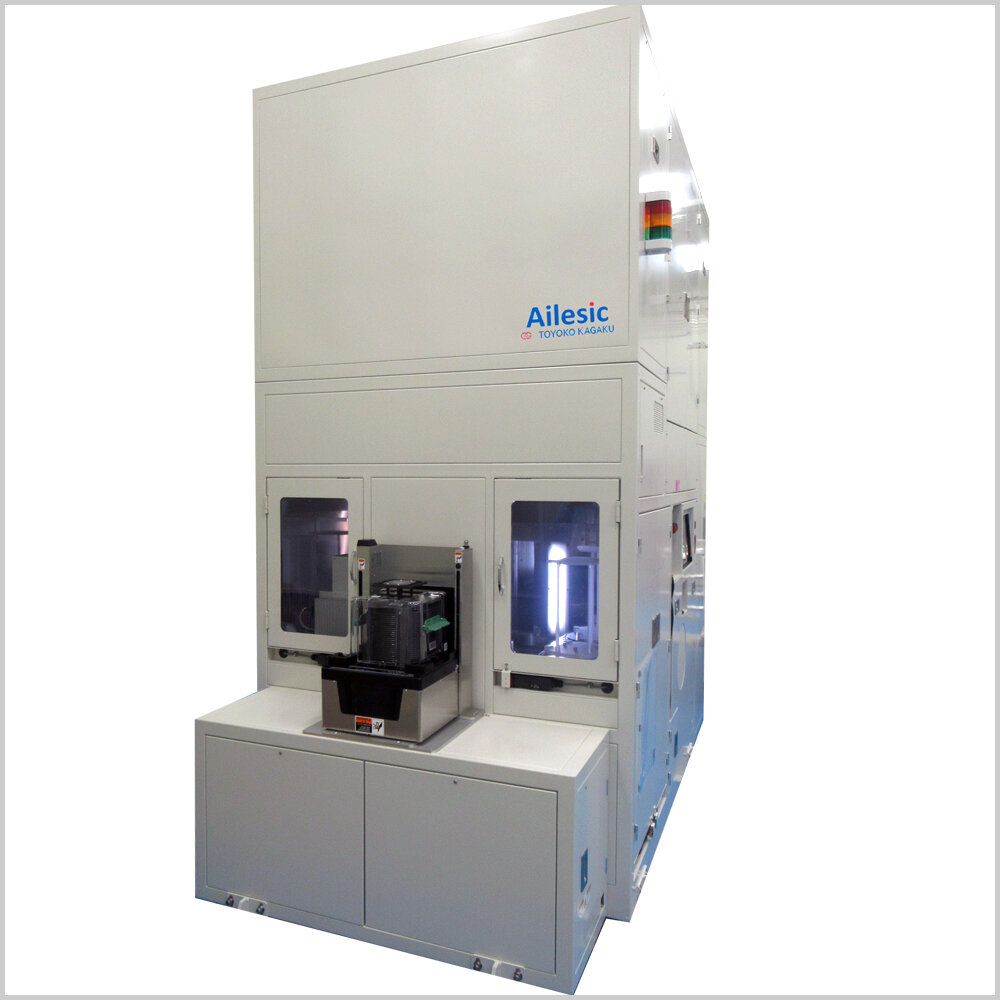

Activation Annealing equipment Ailesic-2000Ⅱ

Features

- Max temp: 2000 degree C to adapt SiC activation anneal process

- Extra rapid heating and cooling concept, realized by our original technology, contributes to minimize process time and adapt customer needs for small lot production and development stage

- Superior stability of process performance, realized by our heating and precise temp control technologies, contributes to stable mass-production

- Various lineup: 100mm R&D to 200mm wafer extra high throughput mass-production models

- Good reputation for operational experience in mass-production fab

Applications

Activation Anneal process ( Post Implantation Anneal )( N2、Ar )

Option ( H2 )

Oxynitriding equipment Ailesic-1400Ⅱ/1500Ⅱ/X1700

Features

- Max temp: 1400/1500/1670 degree C to adapt most of SiC high temperature thermal processes

- Avoiding the risk of metal contamination through the use of All-CVD jigs.

- Extremely low running cost is realized by our original heater design and process jig formation technology.

- Ultra clean, high vacuum and extra high temp processes with RTP ( Rapid Thermal Process ) function are available by using original technology

- Various lineup: 100mm R&D to 200mm wafer mass-production models

- So many and long experiences of running in mass-production fabs

Applications

Oxidation ( O2 )

Post Oxidation Anneal( N2O、NO )

Anneal ( N2, Ar )

Option ( H2 )